If durability matters, sourcing from a seasoned membrane switch manufacturer is key.

If durability matters, sourcing from a seasoned membrane switch manufacturer is key.

Blog Article

All Regarding Membrane Switch: Recognizing Its Layout and Performance

When you believe regarding the control user interfaces in modern-day gadgets, membrane layer buttons often come to mind. Let's explore what collections membrane switches over apart from other control systems.

What Are Membrane Switches?

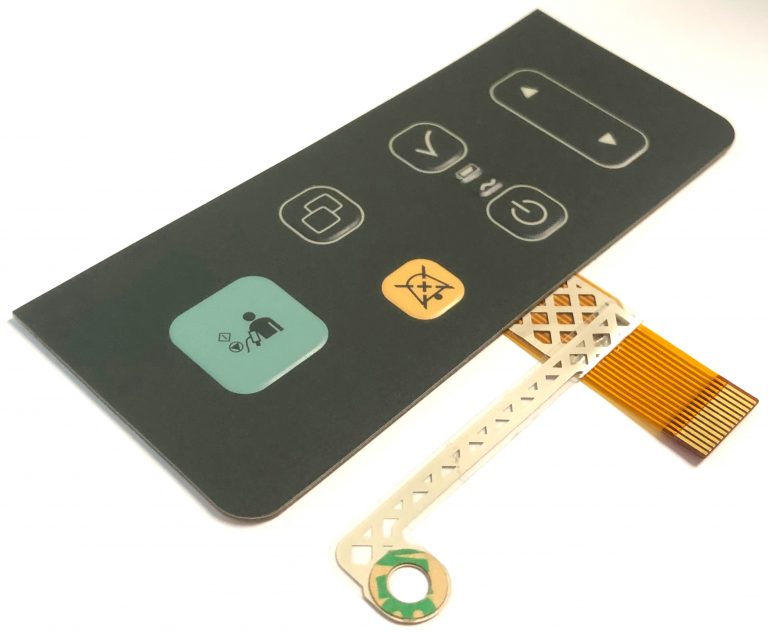

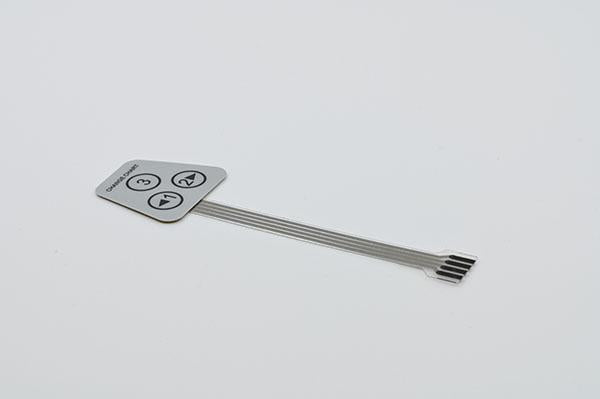

Membrane layer buttons can likewise be tailored relating to form, size, and graphics, enabling manufacturers to produce special interfaces customized to specific products. Overall, membrane layer switches play a considerable duty in enhancing customer experience across a wide array of applications.

How Membrane Layer Switches Work

When you push a trick on a membrane switch, it activates a straightforward yet efficient system. membrane switch manufacturer. The leading layer, frequently made of flexible material, presses down onto a conductive layer below it.

You'll notice that the responsive responses varies based on the button layout, offering either a soft click or a more noticable feedback. When you release the key, the membrane go back to its original position, reopening the circuit and quiting the signal. This procedure happens practically immediately, guaranteeing a responsive user experience.

Membrane layer buttons are preferred due to their toughness and resistance to dust and wetness, making them suitable for numerous applications, from home home appliances to medical tools. Comprehending this operation helps you appreciate their extensive usage.

Secret Components of Membrane Layer Switches

Recognizing the essential elements of membrane buttons is essential for realizing their functionality and layout. The safety layer shields versus environmental aspects and wear, prolonging the switch's lifespan. By comprehending these elements, you'll obtain insight right into how membrane switches operate and their relevance in numerous applications.

Materials Used in Membrane Layer Switch Design

The efficiency and longevity of membrane switches over heavily depend upon the products utilized in their layout. You generally run into polyester and polycarbonate as primary substratums because of their outstanding toughness and flexibility. These materials stand up to scrapes and chemicals, making them excellent for requiring environments.

The conductive layers often utilize silver or carbon, picked for their integrity and conductivity. membrane switch manufacturer. Silver provides remarkable performance, while carbon is an economical option. For the overlay, you might take into consideration a matte or glossy surface, depending upon your aesthetic needs and individual experience

Adhesives play a vital duty too; they bond layers firmly and ensure longevity. Ensure to pick adhesives that hold up against environmental elements like temperature and moisture. Finally, don't neglect the importance of an excellent printing strategy for graphics, as it improves both performance and aesthetic appeal. Picking the appropriate materials will ensure your membrane layer button stands the test of time.

Layout Considerations for Membrane Buttons

While designing membrane layer switches, it's vital to think about numerous elements that influence their capability and individual experience. Start by concentrating on the design and switch size; make certain they're instinctive and simple to browse. Take into consideration the responsive responses you wish to offer-- will customers need an obvious click or a softer touch? Furthermore, think of the products you'll utilize, as they'll impact durability and aesthetics.

Don't overlook the visuals layout; clear labeling and color contrast are substantial for presence. Confirm your design suits ecological aspects, like moisture or temperature level variants, which might impact performance. Keep in mind the importance of screening models with actual users to collect responses and make required changes. This repetitive process aids you improve the design, verifying it satisfies both functional and visual requirements properly. By thoroughly thinking about these aspects, you'll create a membrane layer switch that improves use and complete satisfaction.

Applications of Membrane Layer Buttons

Membrane switches are functional parts found in numerous applications, from commercial equipment to consumer electronics. You'll see their effect in makers that need durable interfaces and in devices that gain from sleek designs. Recognizing these applications aids you value the capability and practicality of membrane layer switches in everyday modern technology.

Industrial Equipment Use

When you're looking to enhance the performance of industrial tools, membrane layer switches supply a reputable option that combines resilience with straightforward style. These buttons are best for rough settings, giving resistance to dust, moisture, and chemicals. You'll find them in control panels for making makers, cooling and heating systems, and clinical gadgets, where precision and responsiveness are essential. Their reduced account suggests they fit flawlessly right into numerous tools, saving useful room while maintaining ease of usage. With adjustable graphics and backlighting options, you can create an instinctive user interface for drivers, boosting performance and security. Plus, their long life-span lowers upkeep costs, making them a smart financial investment for your commercial applications. Embrace membrane layer switches to improve your operations and boost total efficiency.

Customer Electronics Assimilation

In the domain name of consumer electronic devices, membrane switches play a vital duty in boosting customer communication and gadget capability. You'll find them in devices like microwaves, remotes, and pc gaming consoles, giving a smooth means to interact with modern technology. Their streamlined design enables you can check here very easy assimilation right into different products, making controls intuitive and easy to use. With their capacity to include graphics and backlighting, you can enjoy a modern visual that enhances the gadget's overall appearance. Membrane layer switches also guarantee toughness and resistance to dust and moisture, extending the life expectancy of your electronics. By choosing membrane layer buttons, you enhance not simply the performance however also the design of your devices, making everyday communications smooth and delightful.

Advantages and Downsides of Membrane Buttons

While membrane switches use a series of advantages, they also feature some drawbacks that you need to think about. One significant advantage is their portable style, making them suitable for space-constrained applications. They're likewise cost-efficient, giving a durable option with a low production price. On top of that, their smooth surface is very easy to clean, boosting health in environments like health centers.

Nonetheless, there are disadvantages. Membrane switches can have a much shorter lifespan contrasted to mechanical buttons, particularly under heavy usage. They can likewise be less tactile, which could influence customer responses throughout procedure. Moreover, if harmed, repairing them can be challenging and usually calls for complete replacement. Ultimately, their level of sensitivity to extreme temperatures and ecological conditions might limit their efficiency in certain settings. Stabilizing these benefits and drawbacks will certainly assist you identify if membrane buttons are the ideal fit for your job.

Frequently Asked Questions

How Much Time Do Membrane Layer Switches Typically Last?

Membrane layer switches typically last between 5 to one decade, relying on use and ecological conditions. You'll intend to examine factors like wear, direct exposure to moisture, and temperature fluctuations to gauge their longevity successfully.

Can Membrane Layer Switches Be Custom-made for Certain Designs?

Yes, you can tailor membrane layer buttons to fit specific styles (membrane switch manufacturer). You'll have the flexibility to pick colors, forms, and designs this hyperlink that match your project's demands, ensuring they blend perfectly with your total visual

What Is the Cost Variety for Membrane Layer Change Manufacturing?

The price range for membrane layer button production usually falls between $1 and $10 each, depending upon elements like layout intricacy, amount, and materials. You can obtain quotes from manufacturers to locate the most effective option.

Are Membrane Changes Water-proof or Immune?

Membrane buttons can be made to be water resistant or immune, depending upon products utilized and construction techniques. If you need them for damp environments, assure you specify those requirements throughout the style procedure.

How Do Membrane Switches Over Contrast to Conventional Switches?

Membrane layer buttons are generally thinner and a lot more flexible than traditional buttons, offering a smooth layout. They're typically simpler to clean visit this website up and integrate, however may not supply the tactile comments you're made use of to with mechanical alternatives.

Verdict

Report this page